Source: Southeast Finance

Financial theory

2024 is a crucial year for the implementation of the "14th Five-Year Plan" and the 40th anniversary of Ningbo becoming the first batch of coastal open cities in China. For 40 years, Ningbo, as one of the most active areas of private economy and innovation, has produced a large number of outstanding enterprises and entrepreneurs, and it is they who have laid a solid foundation and surging power for China's economy.

Ningbo evening news and Ningbo Association of Listed Companies jointly launched a series of reports on "china galaxy Xingyao Ningbo Entering Listed Companies in Ningbo", focusing on listed companies in Ningbo, showing the resilience and vitality of Ningbo's economy in multiple dimensions, and dissecting the genes and codes of Ningbo enterprises' growth through cycles and jointing.

"The volume of orders in hand has returned to a historical high level, and the market demand is rising steadily." Zhang Junbo, general manager of Ningbo Junhe Pump Co., Ltd. said.

Recently, Junhe Co., Ltd. took the lead in releasing the announcement of the pre-increase of semi-annual results in 2024, and it is estimated that the net profit returned to the mother will be 31.79 million yuan to 37.85 million yuan, an increase of 110% to 150% year-on-year. Judging from the data changes, the company's net profit returned to the mother continued to improve on the basis of substantial growth in the first quarter.

Zhang Junbo said that in the past 25 years, from a manufacturer of water pump accessories to an independent manufacturer of water pumps, Junhe has changed from a "supporting role" to a "leading role", and what he will do in the future is to become a "famous corner" in the industry.

How to become a "name"?

Iterative product update is the "axe" for enterprises to seize the market and maintain their competitive advantage.

The pump industry in which Junhe shares are located is an important subdivision of the general machinery industry, and its main products cover four series, including submersible pump, garden pump, deep well pump and fountain pump.

Stepping into the company's product exhibition hall, you are greeted by new products such as intelligent submersible pump, bottom cleaning robot, lithium-ion submersible pump, which were "sold" at the Canton Fair in April this year, and the green color of Qingyishui is the main color of its product rejuvenation.

Not only are there "new clothes", but Junhe shares have been optimized and upgraded in terms of self-weight, performance, assembly and disassembly, and applicable customer groups. For example, under the same power in performance, the lift level is increased by 10% and the water flow rate is increased by 70%; Household cleaning pump, on the basis of making it easy for female customers to use, also simplifies the steps of disassembly and use.

These not only reflect the technical iteration of Junhe, but also reveal its determination to open up the domestic market. At present, the business model of Junhe has changed from original equipment manufacturing (OEM) to independent brand model (OBM).

"The market cannot be copied, and our overseas model may not be applicable to China." Zhang Junbo said that in China, efficient production has become a standard configuration, and we should do a series of "homework" on market expansion and category expansion.

In fact, the marketing department of Junhe continued to investigate and analyze the market differences at home and abroad six years ago, and officially launched the domestic market strategy in 2020.

In the domestic sales mode, Junhe shares do not stick to the traditional production and sales mode, but adopt the dealer buyout sales mode, give full play to the advantages of downstream partners in local channels, and jointly build a "one-stop" warehouse center with them to provide one-piece distribution and reduce operational risks such as capital and inventory. In addition, Junhe shares also provide brand support for the whole process of warehouse center from site selection, decoration to opening.

In January this year, the first offline store of Junhe Co., Ltd. opened in Ningbo, and then a number of warehouse stores were launched-Changchun in March, Zhengzhou in May and Foshan in June ... This year, Junhe Co., Ltd. will open 10 city stores to welcome customers, and will expand to 37 cities across the country in the next three years. At present, the first offline store is in the high-speed growth period, and the sales volume is expected to reach 50 million to 80 million yuan in 2024.

It is worth noting that in terms of category expansion, Junhe shares are not limited to self-operated products.

In terms of self-operated products, in the past two years, Junhe has also added cleaning machines and power tools, among which high-pressure cleaning machines can be applied to task scenes such as yard cleaning and car cleaning; Power tools products range from basic handheld to customized, and can be used in many industries such as construction engineering, interior decoration, automobile maintenance and assembly. In addition, in the field of commercial pumps, Junhe has also developed commercial pump projects such as construction and agricultural breeding.

In addition, Junhe shares have also created a "one-stop purchasing platform for Junhe hardware and electrical machinery".

"Although we are a subdivision of the pump industry, its volume cannot be underestimated." Zhang Junbo introduced that in addition to Junhe's self-operated products, the platform also integrates upstream and downstream manufacturers in the supply chain. What we need to do is to let users complete the required products in one place, and at the same time reduce intermediate links to achieve "three wins" for users, customers and themselves.

At present, the sales ecosystem of Junhe shares has formed a complete closed loop. "At present, OBM's own brand mainly focuses on the domestic market, and the overseas market with high revenue ratio, as the first' defense line' of the company's performance, will gradually promote this model and upgrade the domestic and international business double cycle." Zhang Junbo said.

At present, Junhe shares have settled in JD.COM, Tmall, Tik Tok and other domestic e-commerce platforms, while overseas online sales are conducted on Amazon and other platforms with the independent e-commerce brand "Blue Fin". The 2023 annual report shows that the company's independent online brand revenue was 19.9813 million yuan, up about 60% year-on-year, and the gross profit margin reached 67.92%.

How to play the role of "corner"?

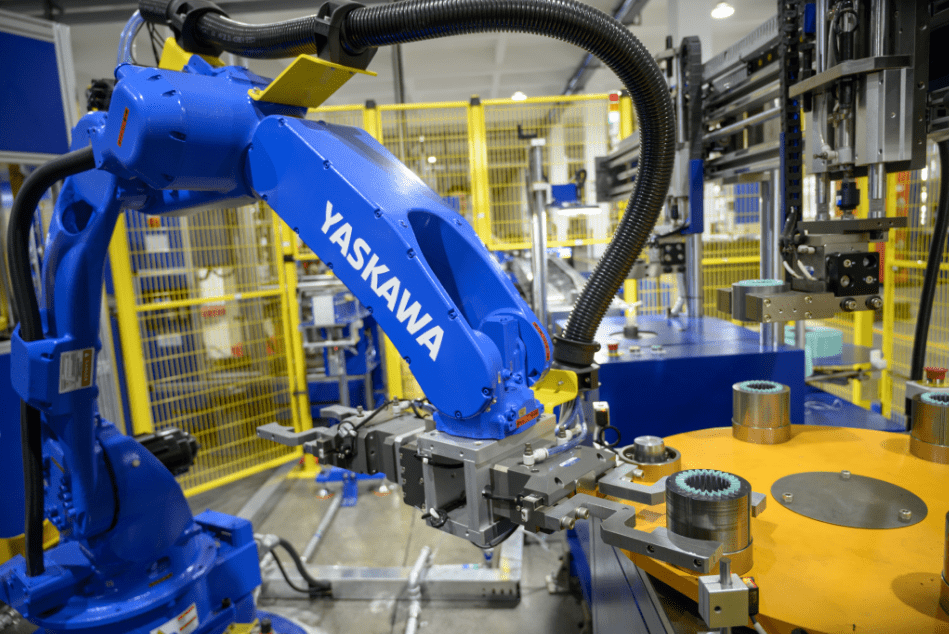

In its stator (stator and rotor assembly of induction motor) production workshop, a mechanical arm operates two production lines; In the water pump producing area, the production machinery can switch the product model with one key for production; Auto production line is connected to the intelligent lifting logistics warehouse through the AGV car ... In the 70,000-square-meter standard workshop of Junhe Intelligent Technology Industrial Park, the reporter witnessed the concrete presentation of digital production, a new quality productivity.

Zhang Junbo said that a digital and intelligent production base is one of the company's core competitiveness.

As early as 2021, Junhe shares have entered a new era of 5G smart manufacturing, achieving an automation degree of over 85% and an annual output of 6 million units. At this point, Junhe shares have also become a leading digital high-end enterprise in the industry.

"This production line can switch the production model with one button, and at the same time, it can produce about 3,000 units per day, which is three times the efficiency of ordinary production lines." Before a "trump card" production line of Junhe, Cao Lei, the mechanical maintenance department of submersible pump workshop, told the reporter that Junhe shares planned digital production as early as 2008, and the production line cost more than 2.6 million yuan to build, which is compatible with most of the company's products. At present, the second intelligent production line that can produce all kinds of products of Junhe shares has entered the debugging stage.

On the basis of extremely flexible production links, the production line of Junhe Co., Ltd. has also realized network monitoring of the whole production line, and the production efficiency has increased by more than 50% compared with the traditional model. At the same time, it has the traceability of the whole process, such as who tightens a nut and whether it meets the standard.

In addition, Junhe shares also integrate the application of new technologies such as industrial Internet, artificial intelligence (visual inspection), digital twinning, 5G, etc., and realize the digital management and control of the whole business process, running through the value chain to the Internet.

Following the production line, the products will be delivered to the three-dimensional intelligent warehouse by "AGV" after finally passing 100% safety inspection, performance test and waterproof test. The main body of the warehouse is a hollow building with a height of 34 meters, and there are 20,000 positions in the warehouse. The fully automatic operating system ensures the accurate scheduling of materials, greatly improving the efficiency of warehouse operation, and can complete the order processing only by manipulating the small screen.

It is worth noting that the digital intelligent production line has also brought more overseas opportunities for Junhe shares. Zhang Junbo told reporters that many merchants, based on their favor for the efficiency of the company's production line, have placed orders for the new Junhe Thailand factory that "China" will build this year.

Not only is the number of production lines intelligent, but the products of Junhe shares are becoming more and more intelligent-

The newly developed WQD sewage pump can be equipped with a float switch, which can control the start and stop of the pump according to the liquid height to prevent dry burning;

The garden pump can be remotely controlled and controlled by Junhe's own APP;

Intelligent submersible pump has many functions, such as automatic start and stop, regular operation, etc., to realize automatic adjustment of inlet water flow under low suction working condition;

The high-efficiency submersible pump with adjustable suction height has a frequency converter that can automatically adjust the pump speed according to the water source to achieve the best working condition;

......

Among them, the high-efficiency submersible pump with adjustable water absorption height has formed sales of more than 600,000 yuan as of May this year. With the arrival of the sales season in the second half of 2024, this product is expected to bring more surprises.

"We hope to build a more beautiful and intelligent life by giving product ideas." Zhang Junbo said that achieving the same frequency as the client's demand is the "first-hand information" for product optimization. The lithium-ion oil pump produced by the company was jointly developed with TTI Company of the United States, and the company also cooperated with international brand manufacturers such as KACH to develop.

At present, Junhe shares more than 800 specifications and models, and has obtained many international product certifications such as GS, CE, EMC and UL.

Disclaimer: All information provided in this article is for reference only and does not constitute any investment advice.